Computing on the Edge–Other Design Considerations for the Edge: Part 2

Thu, 02 Feb 2023 15:30:52 -0000

|Read Time: 0 minutes

The previous blog discussed the physical aspects of a ruggedized chassis, including short depth and serviceability. The overarching theme being that of creating a durable server, in a form factor that can be deployed in a wide range of Telecom and Edge compute environments.

This blog will focus on the inside of the server, specifically design aspects that cover efficient and long-term, reliable server operations. This blog covers the following topics:

- Optimal Thermal Performance

- Power Efficiency

- Contaminant Protections and Smart Bezel Design

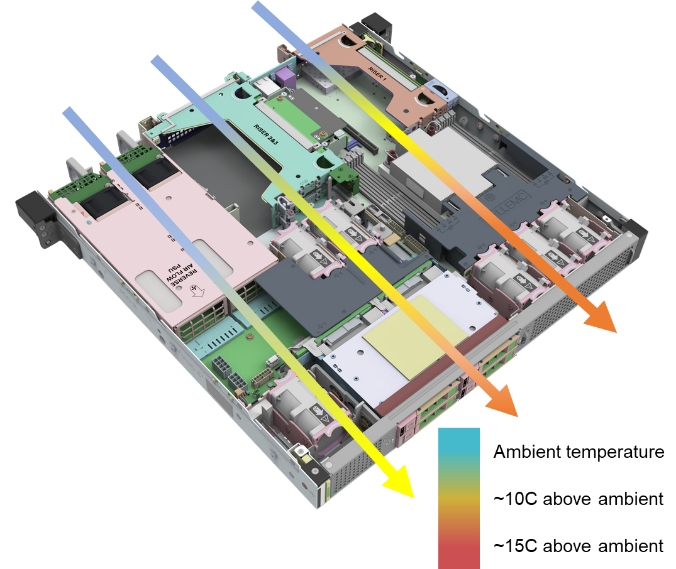

Optimal thermal performance Figure 1. Serial Heat Rise Example from Front to Back

Figure 1. Serial Heat Rise Example from Front to Back

Certainly, one of the greatest challenges of Edge Server Design is architecture and layout. It is extremely challenging to optimize airflow such that heat is efficiently dissipated over the entire operational temperature and humidity range.

In an Edge Server, there are still the same compute, storage, memory, and networking demands required for a traditional data center server. However, the designers are dealing with 30 percent less real estate to work with—and even less space when dealing with some of the sledded server architectures, such as with Dell’s new PowerEdge XR4000 Server.

These design restrictions typically result in components being placed much closer together on the motherboard and a concentration of heat creation in a smaller area. Smart component placement, which mitigates pre-heated air from passing over other sensitive components and advanced heat sinks specifying high-performance fans and the use of air channels to internally direct air through the server, is critical to creating server designs that can tolerate temperature extremes without creating excessive hotspots in the server.

These designs are repeatedly simulated and optimized using a Computational Fluid Dynamics (CFD) application. Hot spots are identified and mitigated until a design is created that maintains all active components within their specified operating temperatures, over the entire operational range of the overall server. For example, for NEBS Level 3 this would range from -5C to +55C, as discussed in the third blog of this series.

Bringing together these server performance requirements, thermal dissipation challenges, component selection, and effective airflow simulations, while involving considerable engineering and applied science is very much an art form. A well-designed server is remarkable not only in its performance but the efficiency and elegance of its layout. Perhaps that’s a little overboard, but I can’t help but admire an efficient server layout and consider all the design iterations, time, engineering efforts and simulations that went into its creation.

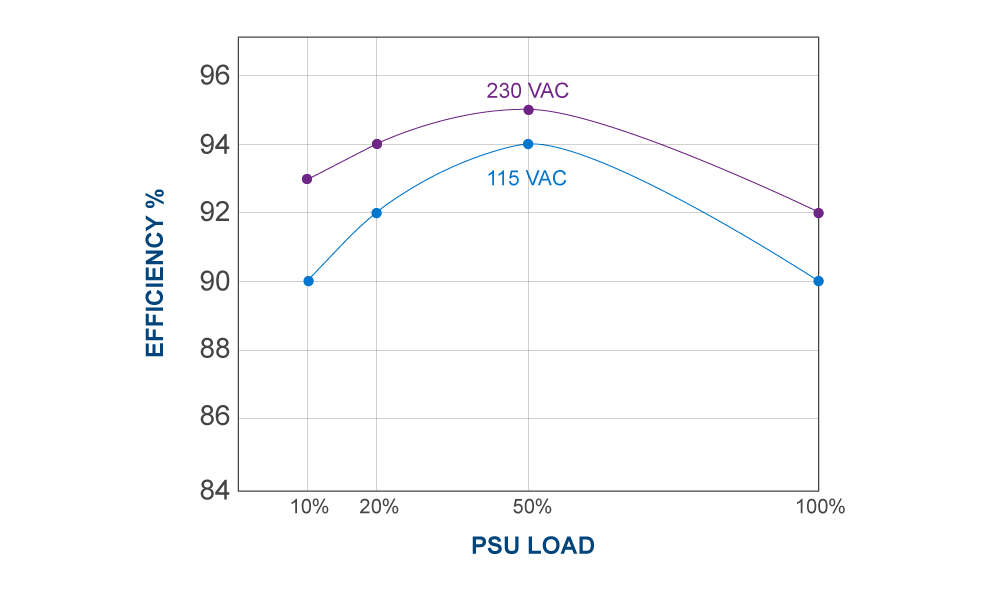

Figure 2. Example 80PLUS Platinum Efficiency CorePower efficiency

Figure 2. Example 80PLUS Platinum Efficiency CorePower efficiency

Having high-efficiency Power Supply Units (PSUs) options, that support multiple voltages (both AC and DC) and multiple PSU capacities will allow for the optimal conversion of input power (110VAC, 220VAC, -48VDC) server consumable voltages (12VDC, 5VDC).

Power Supplies operate most efficiently in a utilization range. PSUs are generally rated with a voluntary certification, called 80PLUS, which is a rating of power conversion efficiency. The minimum efficiency is 80 percent for power conversion rating. The flip side of an 80 percent efficiency rating, is that 20 percent of the input power is wasted as heat. Maximum PSU efficiency rating is currently around 96 percent. Of course, the higher the efficiency the higher the price of the PSU. The increasing costs of electricity globally is dimensioning the PSU, resulting in significant TCO savings.

Ensuring that a server vendor has multiple PSU options that provide optimal PSU efficiencies, over the performance range of the server can save hundreds to thousands of dollars in inefficient power conversion over the lifetime of the server. If you also consider that the power conversion loss represents generated heat, the potential savings in cooling costs are even greater.

Contaminant protection and Smart Bezel design

GR-63-Core specifies three types of airborne contaminants that need to be addressed: particulate, organic vapors, and reactive gases. Organic vapors and reactive gases can lead to rapid corrosion, especially where copper or silver components are exposed in the server. With the density of server components on a motherboard increasing from generation to generation and the size of the components decreasing, corrosion becomes an increasingly complex issue to resolve.

Particulate contaminants, which include particulates—such as salt crystals on the fine side and common dust and metallic particles like zinc whiskers on the coarse side—can cause corrosion but can also result in leakage, eventual electrical arcing, and sudden failures. Common dust build-up within a server can reduce the efficiency of heat dissipation and dust can absorb humidity that can cause shorts and resulting failures.

Hybrid outdoor cabinet solutions may become more common as operators look toward reducing energy costs. These would involve combination of Air Ventilation (AV), Active Cooling (AC), and Heat Exchangers (HEX). Depending on the region AV+AC (warmer) or AV+HEX (cooler) can be used to efficiently evacuate heat from an enclosure, only falling back on AC and HEX when AV cannot sufficiently cool the cabinet. However, exposure to outside air brings in a whole new set of design challenges, which increases the risk of corrosion.

One method of protection employed is a Conformal Covering is a protection method that combats corrosive contaminates in hostile environments. This is a thin layer of a non-conductive material that is applied to the electronics in a server and acts as a barrier to corrosive elements. This layer and the material used (typically some acrylic) is thin enough that its application does not impede heat conduction. Conformal Coverings can also assist against dust build-up. This is not a common practice in servers due to the complexity of applying the coating to the multiple modules (motherboard, DIMMs, PCIe Cards, and more) that compose a modern server and is not without cost. However, the tradeoff of coating a server compared to the savings of using AV may make this practice more common in the future.

Using a filtered bezel is a common option for dust. These filters block dust from entering the server but not keep dust out of the filter. Eventually, the dust accumulated in the filter reduces airflow through the server which can cause components to run hotter or cause the fans to spin at a higher rate consuming more electricity.

Periodically replacing filters is critical—but how often and when? The use of Smart Filter Bezels can be an effective solution to this question. These bezels notify operations when a filter needs to be swapped and may save time with unnecessary periodic checks or rapidly reacting when over-temperature alarms are suddenly received from the server.

Conclusion

The last two blogs in this series covered a few of the design aspects that should be considered when designing a compute solution for the edge that is powerful, compact, ruggedized, environmentally tolerant and power efficient. These designs need to be flexible, deployable into existing environments, often short-depth, and operate reliably with a minimum of physical maintenance for multiple years.

Related Blog Posts

Dell Shifts vRAN into High Gear on PowerEdge with Intel vRAN Boost

Thu, 17 Aug 2023 18:33:05 -0000

|Read Time: 0 minutes

What has past

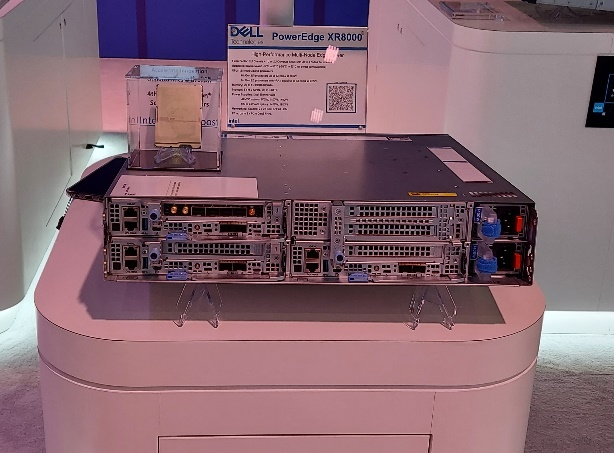

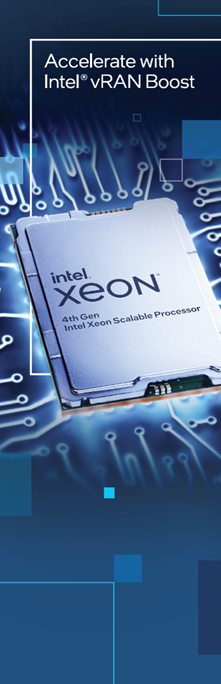

Mobile World Congress 2023 was an important event for both Dell Technologies and Intel that marked a true foundational turning point for vRAN viability. At this event, Intel launched its 4th Gen Intel Xeon Scalable processor, with Intel vRAN Boost, and Dell announced two new ruggedized server platforms, the PowerEdge XR5610 and XR8000, with support for vRAN Boost CPU SKUs.

The features and capabilities of the PowerEdge XR5610 and XR8000 have been highlighted in previous blogs and both have been available to order since May 2023. These new ruggedized servers have been evaluated and adopted as Cloud RAN reference platforms by NEPs such as Samsung and Ericsson. Short-depth, NEBS certified and TCO-optimized, these servers are purpose-built for the demanding deployment environments of Mobile Operators and are now married to the Intel vRAN Boost processor to provide a powerful and efficient alternative to classical appliance options.

What is now

Starting August 16, 2023, the 4th Gen Intel Xeon Scalable processor with Intel vRAN Boost is available to order with the PowerEdge XR5610 and XR8000. These two critical pieces of the vRAN puzzle have been brought together and are now available to order from our PowerEdge XR Rugged Servers page with the following CPU SKUs.

| CPU SKU | Cores | Base Freq. | TDP |

|---|---|---|---|

6433 N | 32 | 2.0 | 205 W |

5423 N | 20 | 2.1 | 145 W |

6423 N | 28 | 2.0 | 195 W |

6403 N | 24 | 1.9 | 185 W |

Table 1. Intel vRAN Boost SKUs available today from Dell

Additional details on these new CPU SKUs and all 4th Gen Intel® Xeon® Scalable processors can be found on the Intel Ark Site.

These processors, with Intel vRAN Boost, integrate key acceleration blocks for 4G and 5G Radio Layer 1 processing into the CPU. These include:

- 5G Low Density Parity Check (LDPC) encoder/decoder

- 4G Turbo encoder/decoder

- Rate match/dematch

- Hybrid Automatic Repeat

- Request (HARQ) with access to DDR memory for buffer management

- Fast Fourier Transform (FFT) block providing DFT/iDFT for the 5G Sounding Reference Signal (SRS)

- Queue Manager (QMGR)

- DMA subsystem

One of the most interesting features of the vRAN Boost CPU is how this acceleration block is accessed by software. Although it is integrated on-chip with the CPU, the vRAN Boost block still presents itself to the Cores/OS as a PCIe device. The genius of this approach is in software compatibility. Virtual Distributed Unit (vDU) applications written for the previous generation HW will access the new vRAN Boost block using the same standardized, open APIs that were developed for the previous generation product. This creates a platform that can support past, present (and possibly future) generations of Intel’s vRAN optimized HW with the same software image.

What is to come

Prior to vRAN Boost, the reference architecture for vDU was a 3rd Gen Intel Xeon Scalable processor along with a FEC/LDPC accelerator, such as the Intel vRAN Accelerator ACC100 Adapter, and most today’s vRAN deployments can be found with this configuration. While the ACC100 does meet the L1 acceleration needs of vRAN it does this at a price, in terms of the space of an HHHL PCIe card and at the cost of an additional 54 W of power consumed (and cooled). In addition, using a PCIe interface will further reduce additional I/O expansion options and impact the ability to scale in-chassis due to slot count – both of which are alleviated with vRAN Boost.

With the new Intel vRAN Boost processors’ fully integrated acceleration, Intel has taken a huge step in closing the performance gap with purpose-built hardware, while remaining true to the “Open” in O-RAN.

Intel says that, compared to the previous generation, the new Intel vRAN Boost processor delivers up to 2x capacity and ~ 20% compute power savings compared to its previous generation processor with ACC100 external acceleration. At the Cell Site, where every watt is counted, operators are constantly exploring opportunities to reduce both power consumption and the associated “cooling tax” of keeping the HW in its operational range, typically within a sealed environment.

Dell and Intel have worked together to provide early access Intel vRAN Boost provisioned XR5610s and XR8000s to multiple partners and customers for integration, evaluation, and proof-of-concepts. One early evaluator, Deutsche Telekom, states:

“Deutsche Telekom recently conducted a performance evaluation of Dell’s PowerEdge XR5610 server, based on Intel’s 4th Gen Intel Xeon Scalable processor with Intel vRAN Boost. Testing under selected scenarios concluded a 2x capacity gain, using approximately 20% less power versus the previous generation. We aim to leverage these significant performance gains on our journey to vRAN.”

-- Petr Ledl , Vice President of Network Trials and Integration Lab and Access Disaggregation Chief Architect, Deutsche Telekom AG

With such a solid industry foundation of the telecom-optimized PowerEdge XR5610s/XR8000s, and 4th Gen Intel Xeon Scalable processors with Intel vRAN Boost, expect to see accelerated deployments of open, vRAN-based infrastructure solutions.

Dell’s PowerEdge XR4000 for Telecom/Edge Compute

Wed, 08 Feb 2023 18:04:19 -0000

|Read Time: 0 minutes

Compute capabilities are increasingly migrating away from the centralized data center and deployed closer to the end user—where data is created, processed, and analyzed in order to generate rapids insights and new value.

Dell Technologies is committed to building infrastructure that can withstand unpredictable and challenging deployment environments. In October 2022, Dell announced the PowerEdge XR4000, a high-performance server, based on the Intel® Xeon® D Processor that is designed and optimized for edge use cases.

Figure 1. Dell PowerEdge XR4000 “rackable” (left) and “stackable” (right) Edge Optimized Servers

The PowerEdge XR4000 is designed from the ground up with the specifications to withstand rugged and harsh deployment environments for multiple industry verticals. This includes a server/chassis designed with the foundation requirements of GR-63-CORE (including -5C to +55C operations) and GR1089-CORE for NEBS Level 3 and GR-3108 Class 1 certification. Designed beyond the NEBS requirements of Telecom, the XR4000 also meets MIL-STD specifications for defense applications, marine specifications for shipboard deployments, and environmental requirements for installations in the power industry.

The XR4000 marks a continuation of Dell Technologies’ commitment to creating platforms that can withstand the unpredictable and often challenging deployment environments encountered at the edge, as focused compute capabilities are increasingly migrating away from the Centralized Data Center and deployed closer to the End User, at the Network Edge or OnPrem.

Attention to a wide range of deployment environments creates a platform that can be reliably deployed from the Data Center to the Cell Site, to the Desktop, and anywhere in between. Its rugged design makes the XR4000 an attractive option to deploy at the Industrial Edge, on the Manufacturing Floor, with the power and expandability to support a wide range of computing requirements, including AI/Analytics with bleeding-edge GPU-based acceleration.

The XR4000 is also an extremely short depth platform, measuring only 342.5mm (13.48 inches) in depth which makes it extremely deployable into a variety of locations. And with a focus on deployments, the XR4000 supports not only EIA-310 compatible 19” rack mounting rails, but also the “stackable” version supports common, industry-standard VESA/DIN rail mounts, with built-in latches to allow the chassis to be mounted on top of each other, leveraging a single VESA/DIN mount.

Additionally, both Chassis types have the option to include a lockable intelligent filtered bezel, to prevent unwanted access to the Sleds and PSUs, with filter monitoring which will create a system alert when the filter needs to be changed. Blocking airborne contaminants, as discussed in a previous blog, is key to extending the life of a server by reducing contaminant build-up that can lead to reduced cooling performance, greater energy costs, corrosion and outage-inducing shorts.

The modular design of the XR4000, along with the short-depth Compute Sled design creates an easily scalable solution. Maintenance procedures are simplified with an all-front-facing, sled-based design.

Conclusion

Specifying and deploying Edge Compute can very often involve selecting a Server Solution outside of the more traditional data center choices. The XR4000 addresses the challenges of moving to compute to the Edge with a compact, NEBS-compliant, and ruggedized approach, with Sled-based servers and all front access, reversible airflow and flexible mounting options, to provide ease of maintenance and upgrades, reducing server downtime and improving TCO.