Next Generation PowerEdge Servers Implement Eco-Friendly DesignStrategies

Download PDFMon, 16 Jan 2023 13:44:29 -0000

|Read Time: 0 minutes

Summary

By increasing efficiencies, removing excess material, and standardizing design concepts, Dell EMC has continued to refine how to effectively contribute to the eco-friendly movement. This tech note highlights a few of the design strategies that have been implemented for PowerEdge servers that preserve resources and reduce the overall footprint made when manufacturing products.

Eco-Friendly Strategies

To continue leading the movement for more eco-friendly server designs, the Dell EMC Experience Design Group developed PowerEdge servers focusing on front-to-back efficiency and start-to-finish thoughtfulness. By leveraging collaborative resources and collective energies on following these two ideals, the following achievements were made in server resource preservation and footprint reduction.

Efficient Design; From Front to Back

Efficient design focuses on maximizing the amount of work that can be done with the least amount of resources possible. Following this strategy ensures that no space, energy or opportunity is wasted in each box. Customers benefit from a solution that has been designed to output as much work as possible, therefore optimizing the total number of servers needed to meet their data center needs.

PowerEdge Efficiency Achievements

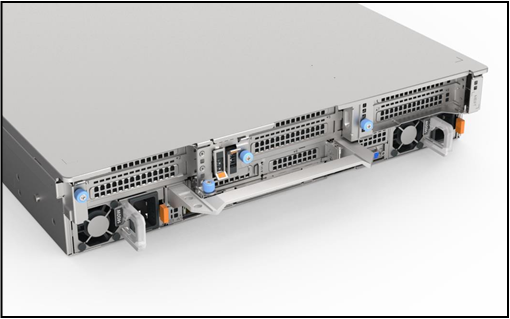

- Drive carrier rail structures now have thin folded metal edges that allow for increased airflow throughout the server chassis. Additionally, the motherboard design has been modified to a T- shape that better organizes airflow distribution throughout the server structure. These design modifications improve fan and power supply usage which reduces total power consumption.

Figure 1: HDD carrier design allows for additional airflow to circulate through the structure

- Refined front-end perforation patterns more effectively prevent the buildup of dust around intake and exhaust vents as well as within the system. This improvement in airflow and fan performance reduces power consumption and enhances energy efficiency. Therefore, PowerEdge products can be further populated with valuable hardware as the efficiency of cool air has increased throughout the box.

Figure 2: Front facing visual of the perforation patterns and IO port locations for the PowerEdge R740

- I/O ports were relocated from within the chassis to the rack ears. Implementing this design change enabled more drive space within the box that customers can utilize for additional capabilities.

Thoughtful Design; From Start to Finish

Thoughtful design focuses on making conscious efforts to create positive environmental impacts, such as reusing resources to minimize the global footprint. PowerEdge servers prioritize thoughtfulness over inconsequential aesthetics to protect and preserve the environment and its future.

PowerEdge Thoughtful Achievements

- Paint was removed from the front end of the server, hard drive carriers and the rear handles. The front end of the server uses hemmed edges to conceal the metal edges, thereby eliminating any need for paint, enhancing the chassis structure, as well as enabling IO components to relocate to the rack ear. Hard drive carriers use a natural finish stainless steel, which reduces the volume of paint used on each server and improves signal integrity. Lastly, the rear handles utilize a die cast process with a bead blast finish as an alternative to using paint. These design changes allowed harmful paints to be removed from multiple processes, therefore producing less air pollutants.

Figure 3: Rear handles are no longer painted, but rather leverage a bead blasted die cast to ensure handle quality remains superb over thousands of cycles.

- Black plastics contain up to 30% recycled resin. Internal components such as latches, air shrouds and casings now use recycled plastics to reduce the production of excess undesired plastics that pollute the oceans and harm our ecosystem.

- Designs are being standardized across the PowerEdge portfolio. Standardizing primary components, such as the chassis, rails and guards, means less prototyping and tooling is required, which must use a small yet significant amount of toxic metal material that will eventually become waste. By moving forwards with a standardization approach, prototyping will be needed much less frequently, and tooling can be reused.

In Conclusion

Dell EMC is committed to manufacturing servers with the future in mind and to make a positive impact on our surroundings. By efficiently and thoughtfully designing PowerEdge products, server technology can continue to advance while simultaneously helping preserve our environment.

Related Documents

Sustainability Improvements for Next-Generation (15G) Dell EMC PowerEdge Servers

Mon, 16 Jan 2023 13:44:21 -0000

|Read Time: 0 minutes

Summary

Dell Technologies relentlessly focuses on improving server sustainability. Designing the PowerEdge product portfolio to work more efficiently allows server technology to continue to advance while simultaneously preserving our environment. This brief DfD will highlight a few key improvements implemented on next-generation (15G) Dell EMC PowerEdge servers.

Overview

While server technology typically becomes more powerful with each passing year, Dell Technologies takes pride in designing PowerEdge servers that are more efficient and sustainable generation-over-generation. Below are a few sustainability improvements for next-generation (15G) PowerEdge servers:

Key Improvements

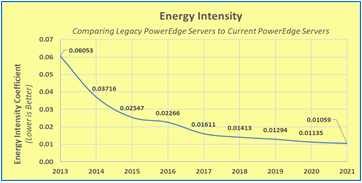

- Next-generation (15G) PowerEdge servers have an Energy Intensity (EI) reduction of 83% over the past 8 years

Figure 1 – The average EI for PowerEdge servers has decreased dramatically over the past eight years, largely due to power, thermal and processor improvements

- Next-generation (15G) Intel PowerEdge servers have increased Energy Efficiency (EE) by 20%-60% over previous Intel PowerEdge servers

15G Energy Efficiency Improvements over 14G | ||

Performance Measurement | Intel Gold 6x30 CPU | Intel Platinum 8x80 CPU |

Idle Power | 23.39% | 59.71% |

Max Power | 36.91% | 19.36% |

PERFCPU | 51.86% | 50.18% |

EffServer | 22.48% | 29.43% |

Perfserver | 47.81% | 55.02% |

Pwrserver | 20.68% | 19.77% |

Figure 2 – The average EE for PowerEdge servers has increased dramatically over the prior-generation, largely due to power, thermal and processor improvements

- 30% of black plastic used in PowerEdge servers is from recycled plastic

- Hardware like latches, air shrouds and casings have been targeted

Understanding the Value of AMDs Socket to Socket Infinity Fabric

Tue, 17 Jan 2023 00:43:22 -0000

|Read Time: 0 minutes

Summary

AMD socket-to-socket Infinity Fabric increases CPU-to-CPU transactional speeds by allowing multiple sockets to communicate directly to one another through these dedicated lanes. This DfD will explain what the socket-to-socket Infinity Fabric interconnect is, how it functions and provides value, as well as how users can gain additional value by dedicating one of the x16 lanes to be used as a PCIe bus for NVMe or GPU use.

Introduction

Prior to socket-to-socket Infinity Fabric (IF) interconnect, CPU-to-CPU communications generally took place on the HyperTransport (HT) bus for AMD platforms. Using this pathway for multi-socket servers worked well during the lifespan of HT, but developing technologies pushed for the development of a solution that would increase data transfer speeds, as well as allow for combo links.

AMD released socket-to-socket Infinity Fabric (also known as xGMI) to resolve these bottlenecks. Having dedicated IF links for direct CPU-to- CPU communications allowed for greater data-transfer speeds, so multi-socket server users could do more work in the same amount of time as before.

How Socket-to-Socket Infinity Fabric Works

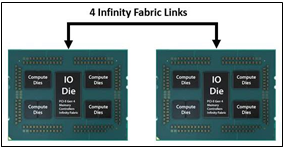

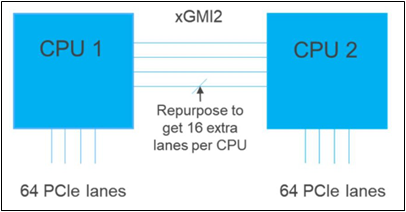

IF is the external socket-to-socket interface for 2-socket servers. The architecture used for IF links is a combo of serializer/deserializer (SERDES) that can be both PCIe and xGMI, allowing for sixteen lanes per link and a lot of platform flexibility. xGMI2 is the current generation available and it has speeds that reach up to 18Gbps; which is faster than the PCIe Gen4 speed of 16Gbps. Two CPUs can be supported by these IF links. Each IF lane connects from one CPU IO die to the next, and they are interwoven in a similar fashion, directly connecting the CPUs to one- another. Most dual-socket servers have three to four IF links dedicated for CPU connections. Figure 1 depicts a high- level illustration of how socket to socket IF links connect across CPUs.

Figure 1 – 4 socket to socket IF links connect two CPUs

The Value of Infinity Fabric Interconnect

Socket to socket IF interconnect creates several advantages for PowerEdge customers:

- Dedicated IF lanes are routed directly from one CPU to the other CPU, ensuring inter-socket communications travel the shortest distance possible

- xGMI2 speeds (18Gbps) exceed the speeds of PCIe Gen4, allowing for extremely fast inter-socket data transfer speeds

Furthermore, if customers require additional PCIe lanes for peripheral components, such as NVMe or GPU drives, one of the four IF links are a cable with a connector that can be repurposed as a PCIe lane. AMD’s highly optimized and flexible link topologies enable sixteen lanes per socket of Infinity Fabric to be repurposed. This means that 2S AMD servers, such as the PowerEdge R7525, have thirty-two additional lanes giving a total of 160 PCIe lanes for peripherals. Figure 2 below illustrates what this would look like:

Figure 2 – Diagram showing additional PCIe lanes available in a 2S configuration

Conclusion

AMDs socket-to-socket Infinity Fabric interconnect replaced the former HyperTransport interconnect in order to allow massive amounts of data to travel fast enough to avoid speed bottlenecks. Furthermore, customers needing additional PCIe lanes can repurpose one of the four IF links for peripheral support. These advantages allow AMD PowerEdge servers, such as the R7525, to meet our server customer needs.