Dell PowerEdge MX7000 and MX760c Liquid Cooling for Maximum Efficiency

Download PDFTue, 18 Apr 2023 15:21:16 -0000

|Read Time: 0 minutes

Introduction

The market trend for high-performance servers to support the most demanding workloads has resulted in newer components, especially CPUs, putting more thermal demands on server design than ever before. Dell’s product engineers have brought new thermal innovation and added the choice of direct liquid cooling (DLC) to the PowerEdge MX7000 modular solution.

To maximize performance and cooling efficiency, customers now have the choice of liquid cooling or air cooling to support low-level to mid-level thermal design power (TDP) CPUs when selecting the MX760c with the latest 4th generation Intel® scalable processors. Implementing direct liquid cooling, or DLC, brings numerous benefits, including dramatically reducing the demand for cold air, so saving the costs of chilling, and reducing the power used to distribute cold air in the data center.

Improved efficiency

Thermal conductivity is basically the ability to move heat, and air’s thermal conductivity is much lower than liquid. (The thermal conductivity of air is 0.031; for water, it is a much higher 0.66. These are average values measured in SI units of watts per meter-kelvin [W·m−1·K−1]). This means that DLC-cooled servers can run top-bin, high-TDP CPUs that otherwise could not operate without throttling with air cooling alone. Also, it takes much less energy to pump liquid coolant through a DLC cold-plate loop than moving a high volume of air that might be cooled through a mechanical chiller. That provides an overall energy savings at the rack and data center level that translate to lower operating costs.

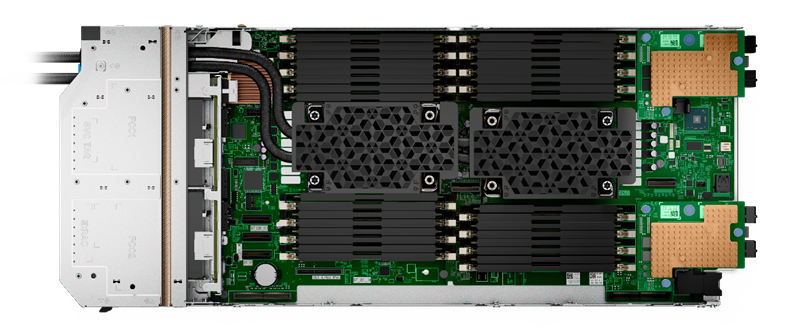

While Dell has offered DLC-cooled servers in previous generations, the MX DLC solution is completely new. It uses the latest cold-plate loop design with Leak Sense, a proprietary method of detecting and reporting any coolant leaks in the server node through an iDRAC alert.

Figure 1. Liquid-cooled PowerEdge MX760c with DLC heat sinks and pipework

The first liquid-cooled Dell server was completed more than ten years ago for a large-scale web company running a dense computer farm. Since then, we have made DLC available on a broad range of PowerEdge platforms, available globally. DLC solutions consist of the server, rack, and rack manifolds to direct coolant to each of the units in a rack, and a Coolant Distribution Unit (CDU). The DLC CDU is connected to the data center water loop and exchanges heat from the rack to the facility water supply. With customers demanding higher levels of performance while also aiming to reduce carbon emissions and energy costs, liquid cooling adoption continues to accelerate. Liquid cooling’s lower energy usage with lower OPEX cost decreases TCO and could produce an ROI within 12 to 24 months depending on the environment.

Table 1. Sample configurations highlighting low fan requirement and power saved by DLC configurations

| Air cooling | Liquid cooling with DLC module | ||||

CPU SKU | 205 W | 225 W | 270 W | 270 W | 300 W | 350 W |

Rear Fan PWR/ Idle CPU Load | 82 W 33% duty | 82 W 33% duty | 82 W 33% duty | 82 W 33% duty | 82 W 33% duty | 82 W 33% duty |

Rear Fan PWR/ 50% CPU Load | 185.7 W 50% duty | 185.7 W 50% duty | 485.3 W 50% duty | 82 W 50% duty | 82 W 33% duty | 82 W 33% duty |

Rear Fan PWR/ 100% Load CPU/MEM/Drive | 1076.8 W 100% duty | 1076.8 W 100% duty | 1076.8 W 100% duty | 111.7 W 39% duty | 111.7 W 39% duty | 111.7 W 39% duty |

Results are based on a four-drive backplane configuration: 4 x 1.92 TB NVMe drives + 24 x 64 GB DDR5 + 2 x 25 Gb mezzanine cards.

Table 2. PowerEdge MX CPU details (offered liquid cooled only)

CPU | TDP | Specifications |

6458Q | 350 W | 4.00 GHz / Max Turbo 3.10 GHz / 60 MB cache / 32 cores |

8458P | 350 W | 2.70 GHz / Max Turbo 3.80 GHz / 82.5 MB cache / 44 cores |

8468 | 350 W | 2.10 GHz / Max Turbo 3.80 GHz / 105 MB cache / 48 cores |

8468V | 330 W | 2.40 GHz / Max Turbo 3.80 GHz / 97.5 MB cache / 48 cores |

8470 | 350 W | 2.00 GHz / Max Turbo 3.80 GHz / 105 MB cache / 52 cores |

8470Q | 350 W | 2.10 GHz / Max Turbo 3.80 GHz / 105 MB cache / 52 cores |

8480+ | 350 W | 2.00 GHz / Max Turbo 3.80 GHz / 105 MB cache / 56 cores |

A liquid cooling solution is limited to a four-drive backplane, E3.S backplane, or diskless configuration. A liquid cooling solution can be provided for all CPU SKUs to support various performance requirements.

Customers can monitor and manage server and chassis power plus thermal data. This information, supplied by the MX chassis and iDRACs, is collected by OpenManage Power Manager and can be reported per individual server, rack, row, and data center. This data can be used to review server power efficiency and locate thermal anomalies such as hotspots. Power Manager also offers additional features, including power capping, carbon emission calculation, and leak detection alert with action automation.

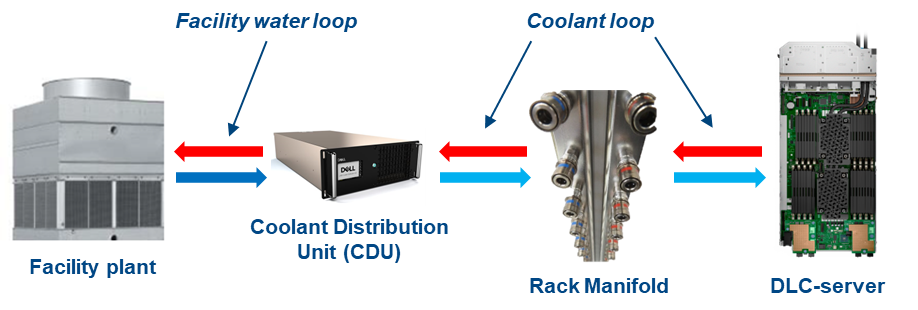

Total solution with direct liquid cooling

The MX760c uses a passive cold-plate loop with supporting liquid cooling infrastructure to capture and remove the heat from the two CPUs. The following image highlights the elements in a complete DLC solution. While customers must provide a facility water connection, a service partner or infrastructure specialist typically provides the remaining solution pieces.

Figure 2. DLC solution elements

Dell customers can now benefit from a pre-integrated DLC rack solution for MX that eliminates the complexity and risk associated with correctly selecting and installing these pieces. The DLC3000 rack solution for MX includes a rack, customer MX rack manifold, in-rack CDU, and each MX chassis and DLC-enabled compute node pre-installed and tested. The rack solution is then delivered to the customer’s data center floor, where the Dell services team connects the rack to facility water and ensures full operation. Finally, Dell ProSupport maintenance and warranty coverage backs everything in the rack to make the whole experience as simple as possible.

Figure 3. DLC3000 MX rack solution (front and rear views)

Moreover, with the DLC solution, the pre-integrated rack can support up to four MX chassis and 32 compute sleds. With top-bin 350 W Xeon Gen 4 CPUs, that translates to over 22 kW of CPU power captured to the DLC cooling solution. It is a major leap in capability and performance, now available for Dell customers.

Conclusion

As Dell offers the 4th generation Intel CPU in air-cooled and liquid-cooled configurations for use with the PowerEdge MX, customers need to review the choice between traditional air cooling and DLC, and understand the benefits of both to make an informed decision. Organizations need to consider server workload demands, capital expenditures (CAPEX) plus operating expense (OPEX), cost of power, and cost of cooling to understand the full life-cycle costs and determine whether air cooling or DLC provides a better TCO.

References

- Tech Talk Video: MX760c DLC walkthrough

- Unlock New MX CPU and Storage Configurations with a Thermally Optimized Air-Cooled Chassis

- The Future of Server Cooling—Part 1. The History of Server and Data Center Cooling Technologies

- Dell PowerEdge MX760c Technical Guide