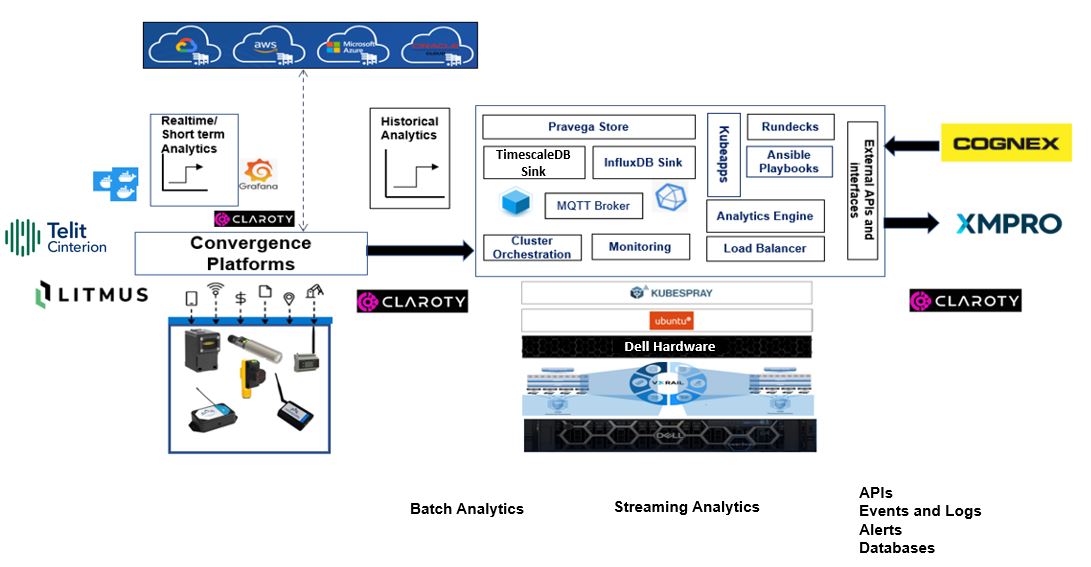

The Dell Validated Design for Manufacturing Edge consists of the following components:

- Three- or four-node Dell VxRail Hyperconverged Infrastructure system

- Dell Streaming Data Platform

- Dell PowerScale flexible and scale-out Network Attached Storage (NAS) solution

- Data convergence platform Telit deviceWISE

- Data convergence platform Litmus

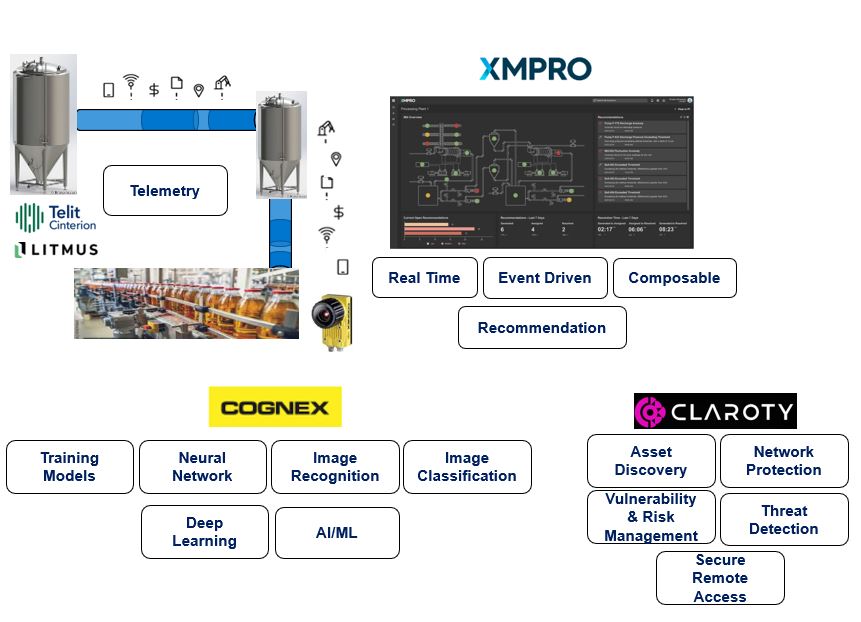

- Computer vision-based anomaly detection, deep learning enabled by Cognex VisionPro, Deep Learning Studio, and Designer

- XMPro no-code digital twin composition platform

- Persistence database platforms including TimescaleDB, InfluxDB, SQLite, Microsoft SQL Server

- Telemetry data ingest from Telit deviceWISE and Litmus leveraging SDP MQTT Agent, and machine vision images and metadata from Cognex persisted in SDP using Python-based integration with SDP REST API

- Collaboration across Telit deviceWISE, Litmus, XMPro, and Cognex applications using data persistence, database sinks, Pravega Search, and REST API-based integrations with SDP

- Data visualization using SDP-based Grafana, as well as XMPro event boards and Cognex dashboards

- External API access for programmatic extensions to enable new use cases

- Industrial gateway devices

- Environmental sensors

- Industrial cybersecurity from Claroty providing asset discovery, vulnerability and risk management, threat detection, network protection, and secure remote access

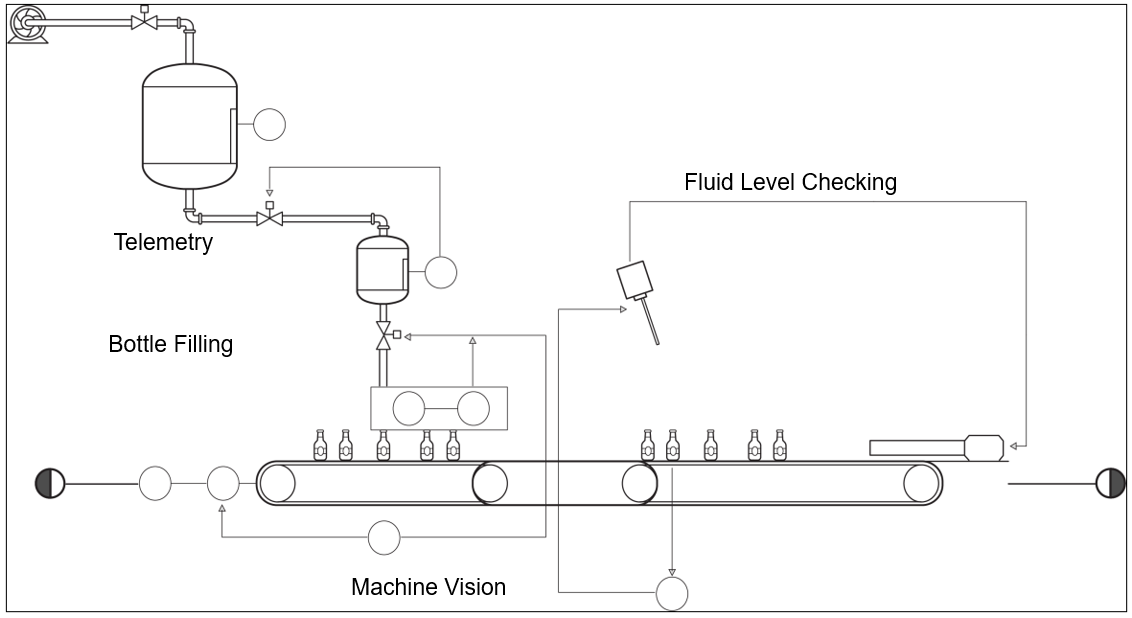

The architecture covered in this DVD for Manufacturing Edge addresses smart manufacturing use cases by incorporating telemetry data sets and protocol convergence, machine vision, and simplified digital twin. In this DVD, a liquid bottling plant is used as a representation of a typical manufacturing environment and integrated various components and Independent Software Vendor (ISV) applications to validate the overall design and generate scale and sizing guidance.

The use cases covered by this design include, among others:

- Overall Equipment Effectiveness (OEE)

- Predictive maintenance

- Remaining useful life of the equipment

- Anomaly detection using telemetry data sets

- Filtration and material levels, temperature, pressure, and other telemetry

- Malfunctioning components

- Leaking pipes

- Anomaly detection using machine vision

- Misaligned and damaged bottles

- Improper seals (misplaced caps) on the bottles

- Incorrect labels

- Process optimization

- Fluid flow correction

- Production line changes by incorporating new sensors and equipment, and deploying them on a digital twin

- Cybersecurity

- Overall intrusion detection and protection for network traffic across various components

- IDMZ and other security considerations

The following figure shows the bottling plant operational flow used by this validated design. The figure shows the validation flow diagram that illustrates how telemetry data and machine vision are used to realize smart manufacturing and digital twin using real-time and historical data sets.

The following is a high-level description of the DVD for Manufacturing Edge:

- VMware vSphere and vSAN support virtual machines (VMs) for Telit Cinterion, Cognex, XMPro, Claroty, and Litmus applications on VxRail.

- One or more sets of VM-based deployments of the various application stacks support a broad range of industrial devices and use cases with role-based access controls, high availability, and disaster recovery considerations.

- Dell Streaming Data Platform provides various database stores on VMs with persistence.

- Telemetry data aggregation by Telit deviceWISE and Litmus support a broad range of protocols and data types.

- Several ISV applications can be deployed on industrial gateways and used to aggregate data to ISV applications running on other layers or on the Streaming Data Platform.

Subsequent chapters describe each of the components in detail and discuss considerations and best practices.