Using Edge Computing to Enhance Customer Experience and Operational Efficiency - Part 2

Thu, 10 Aug 2023 12:41:15 -0000

|Read Time: 0 minutes

As discussed in Part 1, this blog provides a comprehensive analysis of potential edge computing solutions for those current problems in the retail sector, including retail shrink, stocking, and item locations.

In this part, we will be looking at more potential problems as well as suggested solutions for them.

Problem 2: Stocking (Empty store shelves)

Overview

Stocking store shelves is an essential part to keeping up sales in a retail store. Customers expect to find what they need when they visit a store, and they may switch to a competitor if they encounter frequent out-of-stocks. It is essential for retailers to adopt an efficient and effective replenishment strategy that ensures optimal inventory levels and minimizes out-of-stocks. According to retail store IHL Group, shoppers encounter out-of-stocks in as often as one in three shopping trips, about 32% of those being empty shelves.

A common replenishment strategy that some retailers use is to stock store shelves only on specific days, such as once or twice a week. This approach may seem convenient and cost effective, since it would reduce the labor needed to frequently restock the shelves. However, this strategy also has some drawbacks that can harm the sales performance and profitability of the retailer.

Firstly, products sell at different rates. Some products may sell faster than others, and some days may even have higher sales than other days. This means that some products may sell out of stock before the next time the shelves are restocked, while other products take up too much space that can be used to hold other, more sought-after products.

Secondly, not having store shelves stocked continuously lowers the customer satisfaction with the store. The store may not seem reliable if they never have the items in stock, and customers may feel frustrated or disappointed with the store. It is even possible that customers will then switch to a competing retailer to meet their needs.

Real-world scenario

Once, I went to the store to purchase some potato chip. I went to the store on a Friday afternoon after class, one day before the typical restocking. Upon entering the store, I found that all the potato chips were sold out. There were not even corn chips available. Instead of waiting another day for the store to restock, I went to another store and purchased some other brand of chips. As a result of this experience, the first store not only lost the sale of my bag of potato chips but also likely lost the sales from other customers who were looking for chips that day.

Benefits of addressing the problem

Restocking products when they need to be restocked has several benefits that can improve the sales performance and profitability of the retailer. There are some benefits to restocking shelves: you can attract and retain customers, and you can optimize your inventory management.

Customers are more likely to enter and stay in a store that has well-stocked and appealing shelves. They can easily locate the products they want to buy, and they can also discover new products that are tempting to purchase. This can increase the likelihood of impulse purchases and repeat visits, since the customer would be happy with the store.

Restocking shelves can help retailers to monitor their inventory levels and prevent overstocking and understocking. By keeping track of what products are selling well and what products are not, retailers can adjust their orders and promotions accordingly. This can reduce inventory costs, waste, and shrinkage, and improve cash flow and profitability.

Possible solution

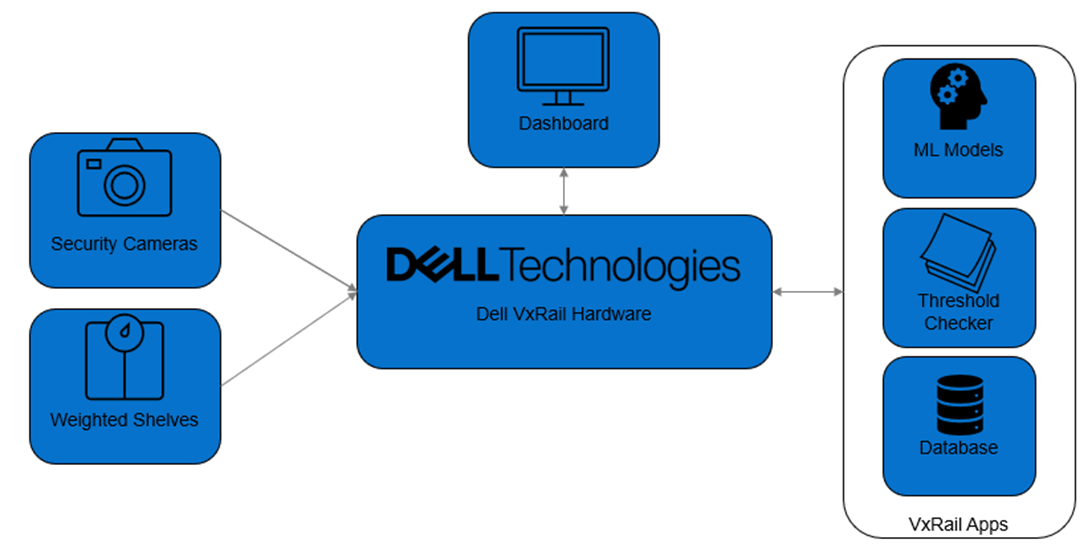

Like in the last solution, you will need a camera system, a Dell VxRail cluster for both compute power and storage, and computer vision applications for analyzing the incoming video feeds. Additionally, the cluster can connect to shelves that gather the weight of the items on top to better represent how many items more accurately there are on the shelf.

In this solution, there will once again be cameras placed in the aisles of the store. The cameras will feed real-time footage to the VxRail cluster, where pre-trained models with knowledge of the products will analyze the footage and determine how many of each product there are left. When the stock of a product in an aisle is running low, the system can alert the employees that the item needs to be restocked.

Sometimes, the shelves are built in a way that is difficult to see how many of a certain item there are in a shelf from how they are lined up. To solve this, the customer can use weighted shelves that record how heavy the items on the shelf are. The sensors in the shelf report back to the VxRail cluster, which combined with the Computer Vision view of the shelves, can be used to get an accurate reading of how many of each item there are on the shelves.

This solution gives the store valuable data regarding store traffic and the items the store needs to purchase more of. If an item is frequently running out of stock, the store may want to look into expanding the shelf space that the item takes up or keeping more of the items in the back. That way, this solution can also help you with inventory management.

Figure 1. Technological diagram

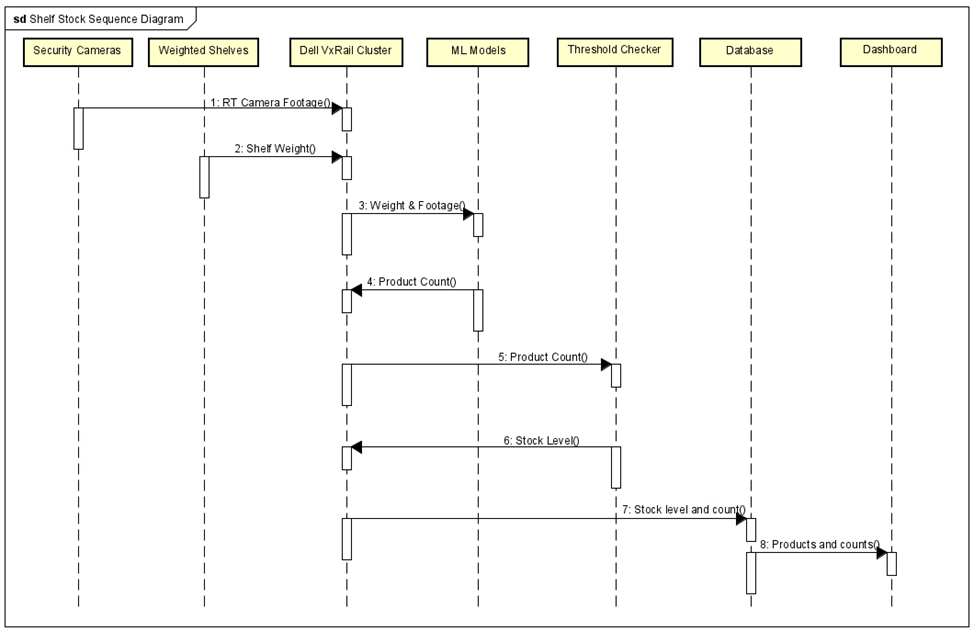

Figure 2. Shelf-stock sequence diagram

In this diagram, the security cameras feed the real-time camera footage of the aisles over to the VxRail cluster. At the same time, the weight sensors in the shelves will send the weight info over to the cluster as well. Both the camera footage and the weight information will be passed over to the ML Models nodes, which can then use the information to count how many of the products there are on the shelves. This count can then be passed back to the cluster, which can hand it off to the Threshold Checker application. The Threshold Checker application, which the store owners can customize to change what amount of an item on a shelf is considered low stock, then checks the status of the amount of the item against the threshold and gives the value back to the cluster, which stores it in the Database. The Dashboard can then show all of the items and their amounts, and which items are in need of restocking.

Problem 3: Storing (Misplaced items)

Overview

One of the challenges that retailers face is customers misplacing items in the store. This can lead to lost sales, and customers may not be able to find the products they are looking for or may purchase a different product instead. Customers often pick up a product at the store, but then leave it in a placed where it does not belong when they realize they do not want it anymore. This creates clutter, confusion, and inefficiency in the store layout and inventory management. Moreover, currently where stores have mobile apps that can tell you what aisle an item is supposed to be in, customers may get frustrated or confused if the app does not match the reality of the store layout. This can damage the customer’s trust and loyalty and reduce the likelihood of repeat purchases. Sometimes when inventory is missing and not accounted for, it has simply been mistaken for another item. Therefore, it is important for retailers to maintain a consistent and accurate inventory system. For more information, see 5 Most Common Reasons for Inventory Discrepancy and How to Resolve Them.

Real-world scenario

One time at the store, I was looking to purchase some cayenne pepper seasoning for a recipe of mine. I went to a local store and checked the store’s mobile app to see if cayenne pepper was in stock. The app indicated that the store had cayenne pepper in stock, so I went down to the correct aisle. Despite going through all the different rows multiple times, I could not find the cayenne pepper. I went to purchase the other ingredients, when I noticed that the cayenne pepper was not in the correct location. If I could not find where the cayenne pepper was misplaced to, the store would have lost my sale.

Benefits of addressing the problem

Solving this problem can have many benefits for both the retailers and the customers. Some of the benefits are improved customer satisfaction, increased sales and revenue, and reduced costs and waste.

Customers would be able to find the products they want more easily and quickly, without having to search the aisles for misplaced items. They can also trust that the products they see on the shelves are fresh, available, and correctly priced.

When products are in their proper locations, they are more likely to catch the attention of potential buyers and generate impulse purchases. Customers are also more likely to buy more items when they have a good shopping experience and can see all the options available.

Misplaced products can cause inventory errors, shrinkage, and spoilage. By keeping the products in the areas that they belong in, retailers can avoid these losses and save money on labor, storage, and disposal. They can also optimize their space utilization and merchandising strategies.

Possible solution

As for the other two solutions, you will need a camera setup, a Dell VxRail cluster for compute power and storage, and computer vision applications for analyzing the incoming video feeds.

This solution will also require the use of cameras in the storefront. Like the first two solutions, the cameras will need to be placed in the aisle to monitor the items there. The cameras will send live camera footage over to the VxRail cluster which has pre-trained models that know all the items. The cameras will be identified based on what aisle they are in, so the apps of the VxRail cluster will know what aisle the item came from as well. The machine learning models will report back what items are in the aisle to a separate app of the VxRail cluster, which will check a database containing items and their locations to make sure that the item is in the proper spot. If it is not, it can alert an employee and they can go and retrieve the item and put it in the proper location.

There is a lot of data that can be gathered in this solution. For example, you can find out what products are being left at what places. If a lot of the same product are being misplaced in the same location, then maybe there is another product nearby that they would rather have. The store can then find these competing brands and decide how they want to organize their store more to encourage more sales. The store could also find products that are more likely to be removed from the cart, and then use that data to determine what products need to be stocked less.

Figure 3. Technological diagram

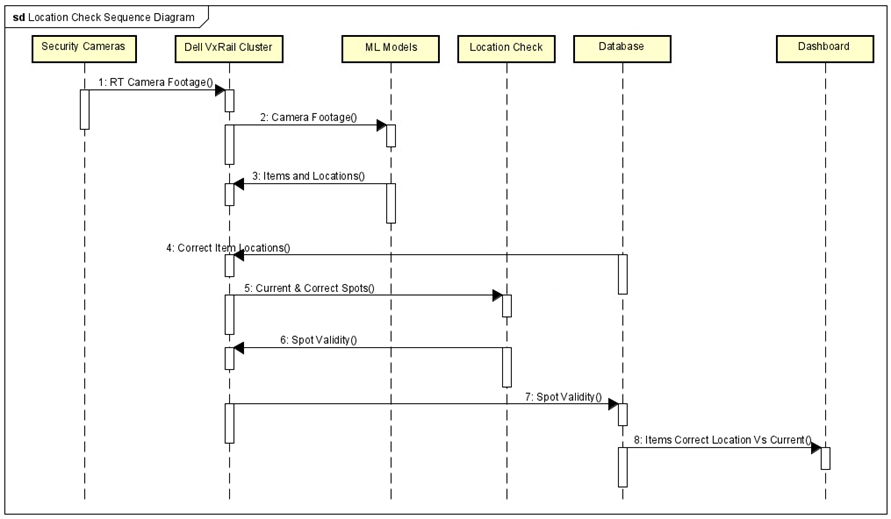

Figure 4. Location check sequence diagram

In this diagram, the security cameras feed the real-time camera footage to the Dell VxRail cluster. The cluster sends that footage to the ML Models, which reports the items there and their current locations. The cluster receives the correct location info from the database, and passes the database info, and the items and their current locations to the location check app. The app will verify that it is in the right spot and will send the state of the item’s location back to the cluster, which can then store it in the database. The store owner’s dashboard can then showcase the locations of the items, and which ones are in the wrong spot.

Read more

For more information about using edge computing to enhance the customer experience and operational efficiency, see Part 1 and Part 3 of this blog.